|

|

|

| As ECU strategies are most often

designed, developed and owned by the ECU manufacturer, Automotive

OEMs need a method of implementing control strategy independent

of the ECU supplier to enable problems found in calibration

and testing work to be overcome more rapidly. |

| |

| Automotive OEMs face pressure

to deliver development programs on time with ever increasing

control strategy complexity due to higher customer expectations

and tightening legislation. “Vehicle manufacturers and ECU

suppliers have widely identified controller strategy development

as a means of differentiating themselves from the competition.

In order to keep pace with the competition a streamlined development

process is necessary” (Rolfsmeier et al, 2003). “Manufacturers

and Suppliers are constantly searching for means to reduce

both time-to-market and development cost. As a kind of solution

to satisfy these requirements Rapid-control prototyping has

established itself as viable technology” (Shin et al, 2003). |

| |

Tools for the purpose are available,

however, the increasing requirements in this area have created

a need for this functionality to be available within or to

coexist seamlessly with calibration tools using the same physical

link to access the target ECU, and needing to operate concurrently.

Despite a requirement existing to date, the integration of

the stimulation of parameters with standard features found

in calibration tools has been limited to implementations that

have had no real time capability, that is loop times and latency

have been unacceptable with general operation being non deterministic.

This limitation is prohibitive to the requirement to use standards

based protocols to robustly run control strategy externally

from the ECU whilst retaining the functionality available

to a calibration engineer by the calibration tool. This has

now been changed with the introduction of the MCS400DR and

MCS400ADR.

Voorburg (2002) shows that there is focus on the anticipated

time savings that can be achieved in the programming, verification

and testing phases of the software development process. The

Software Development process that is outlined does not illustrate

the process of software delivery to the Automotive OEM by

the ECU supplier and outline the calibration process. It needs

to be recognised that due to the way that software is delivered

and subsequently calibrated many unanticipated interactions

will be encountered. By use of RCP in this area, the Automotive

OEM can communicate requirements for software changes to the

ECU vendor. The new requirements can potentially be validated

solutions. The impact of these can at the same time be tested

and engineers working on other systems impacted by these changes

can compensate accordingly.

|

| |

|

| |

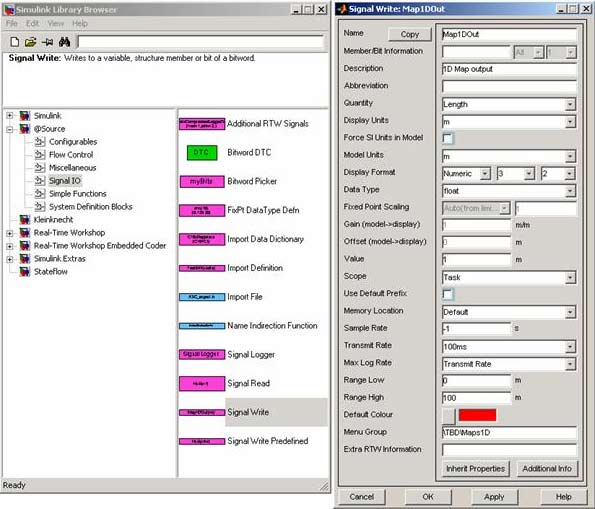

Kleinknecht Gredi calibration

software can also access parameters and variables available

in both the ECU and the RPM as well as other ECUs and data

acquisition equipment that is connected.

Use of the supplied blockset also enables data type handling

of allowing engineers to work in physical units easily; the

generated description file will also have the display model

and limits correctly defined. |

| |

|

| |

| References |

| |

Lemon, K., Dmuchowski, T., Emaus,

B., (2000) Introduction to CAN Calibration Protocol, SAE Technical

Paper 2000-01-0389, Warrendale, Society of Automotive Engineers.

Rolfsmeier, A., Richert, J., Leinfellner, R., (2003) A New

Calibration System for ECU Development, SAE Technical Paper

2003-01-131, Warrendale, Society of Automotive Engineers.

Shin, M., Lee, W., Sunwoo, M., (2003) Implementation-Conscious

Rapid Control Prototyping Platform for Advanced Model-Based

Engine Control, SAE Technical Paper 2003-01-0355, Warrendale,

Society of Automotive Engineers.

Voorburg, F., (2002) Rapid Application Development for Embedded

Systems Using CAN Calibration Protocol, SAE Technical Paper

2002-01-1170, Warrendale, Society of Automotive Engineers. |

| |

|

|

|

|